CT UAV – Awe-Inspiring: the Self-Evolving Composite Molding Plant

In addition to its deep expertise in designing and manufacturing semiconductor chips for UAVs, proprietary algorithms and AI platforms for UAVs, and inventions of video transmission devices for non-GPS or 5G areas, CT UAV continues to shake the global market with its technology for molding fuselages, wings, propellers, and other aircraft parts at its top-tier NAACP-class Composite plant. Let's explore this plant with our reporter!

What is NAACP? Next-Generation Aerospace Advanced Composite Plant (CT UAV NAACP).

Why "Plant" and not "Factory"?

HO CHI MINH CITY, Vietnam, Sept. 11, 2025 (GLOBE NEWSWIRE) -- The CT UAV carbon molding facility is not just a traditional factory but a science-technology-service complex that grows rapidly, establishing deep roots and springing up quickly. The word "plant" emphasizes its ancient meaning of "something that sprung up," taking firm root, developing, and branching out.

A plant can create intangible products such as IP, R&D processes, scientific products, and services like digital systems, energy, and security assurance.

Robot arm at the CT UAV self-evolving composite molding plant

Why "Composite" and not "Carbon fiber"?

It's not limited to Carbon fiber but also includes Kevlar fiber, Zylon fiber, PMI… which have more advanced structures and properties than carbon fiber.

Thus, it is clear that in the vision of CT Group and CT UAV, the NAACP was created with a completely different goal than a conventional composite or carbon processing factory. It is a seed, a platform for continuous updates and deep application of state-of-the-art science and technology.

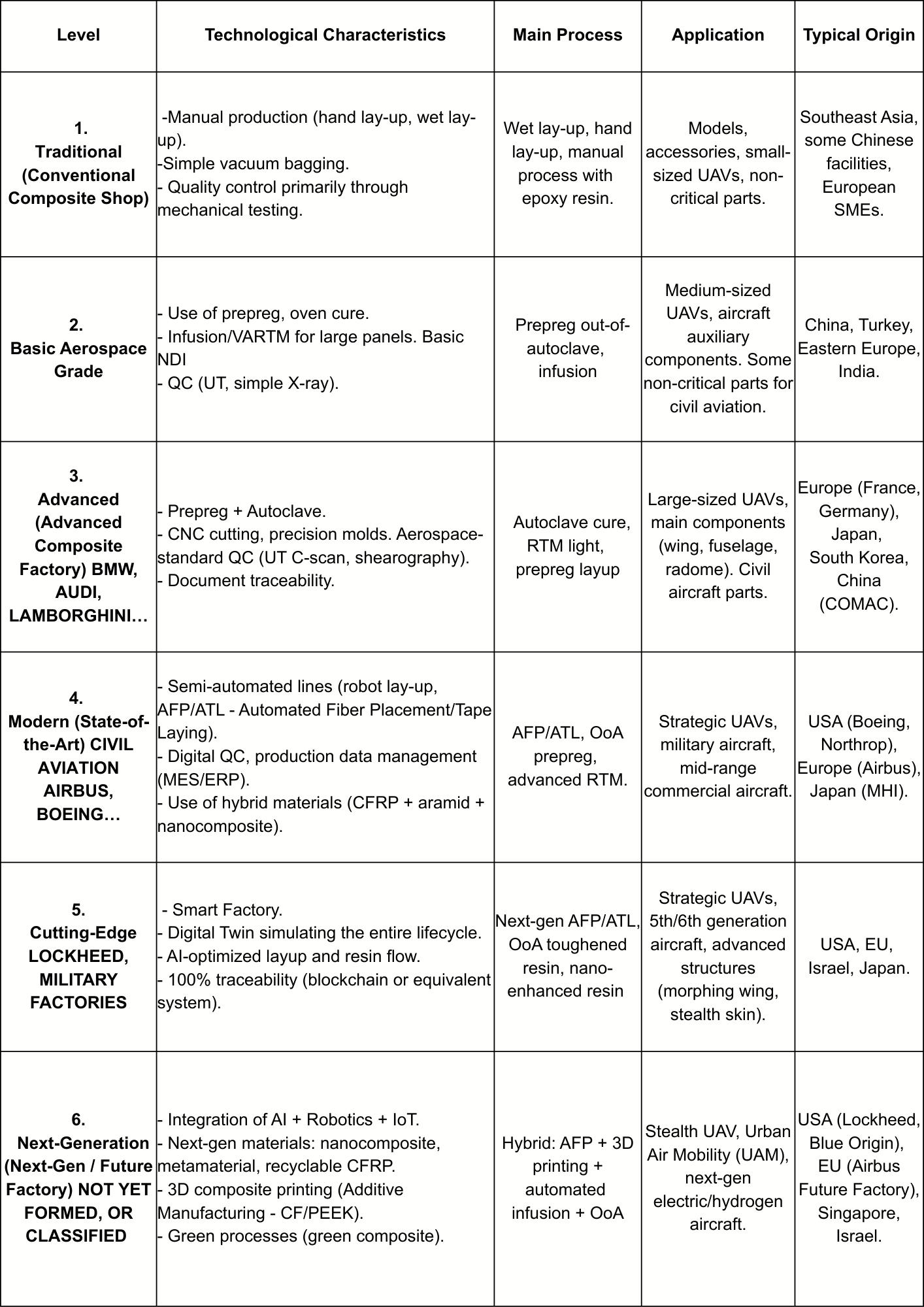

Plant Level Classification:

- Materials: Capability to research, produce, and process advanced composite materials (carbon prepreg, thermoplastic composites, nano-composites).

- Automation Process: Level of automation (hand lay-up → AFP/ATL robot → digital twin).

- Digital Simulation (CAE/CFD/FEM): Ability to predict and optimize structures before production.

- Quality Control (QC/QA): From manual inspection → in-situ sensors, AI defect detection.

- Value Chain: From OEM production level to integration of R&D, supply chain, and product lifecycle logistics.

- Quality & Data Management System: ISO/AS9100 → MES → Digital twin & AI-driven decision making.

1. Next-Gen Materials

- Advanced composite: developing new composite groups: new fiber and matrix phases + modified composites.

- Thermoplastic CFRP (CF/PEEK, CF/PEKK): Developing thermoplastic matrix composites combined with micro fibers.

- Multifunctional composites: integrating capabilities like lightning strike protection, radar absorption, thermal conductivity, and sensing directly into the structure.

-

Green composites: bio-resins, recycling and reuse processes.

2. Simulation + Early-Stage Structural Planning + Experimental Combination

Simulation of failure points, delamination, static-dynamic loads, vibrations, and joint assemblies.

-

Aerodynamics, wind gusts, noise.

Manufacturing Simulation:

- Predicting tear angles and overlaps for AFP/ATL; turning angles during fiber placement to avoid exceeding the rotational limits of AFP/ATL.

- Curing kinetics, heat propagation, and mold cooling to synchronously control the curing process and compensate for shrinkage.

- Simulating RTM/ infusion/ Bladder/ OOA/ Autoclave processes: calculating viscosity, infiltration speed, and optimizing ports.

- Risk prevention and mitigation: structural weaknesses, conflicts in the final product.

-

Using simulation software: such as ANSYS for structural calculations, composite layer structure, composition, and predicting failure points, fatigue, torsion, and stress.

3. Combined + Creative + Customized + Precisely Recorded Production Process

- Additive Manufacturing (3D composite printing): printing UAV wings, skeletons, joints using CF/PEEK (Carbon Fiber/Polyether Ether Ketone – a high-performance engineering plastic with high heat, chemical, and fatigue resistance) or hybrid materials.

- Hybrid process: combining AFP + infusion + 3D printing for rapid manufacturing of molds and prototypes with operational mechanical properties → flexible, saves product development time, reduces R&D costs, and allows for earlier prototype launches.

- Smart OoA Curing: Using diverse shaping methods, combining stages, applying control techniques for resins with special specifications and curing profiles → eliminates the need for an autoclave, reduces energy costs, speeds up production, and achieves superior mechanical properties, allowing for reduced thickness and weight of the UAV body.

- Autoclave curing: using a pressurized oven to create structures with high compaction, low resin content, and an increased strength-to-weight ratio. However, suitable products must be selected to reduce oven operating costs.

-

Developing automated AFP/ATL systems: this is the most advanced manufacturing technology group today, applied to military UAVs, space rocket fuel tanks, and the fuselage of the Boeing 787. It achieves near-absolute precision compared to manual production.

Multi-axis robot lay-up (AFP/ATL): can handle curved panels and complex wing boxes.

- AGV/AMR logistics: autonomous guided vehicles transport molds, materials, and semi-finished products within the plant. Costs are projected to decrease, enabling continuous transport and reducing waiting times.

- Cobots (Collaborative Robots): assist workers in welding, cutting, and sanding. This can be implemented from the early stages of the NAACP as a proactive solution for technology development, saving costs, and significantly reducing future R&D time because the Automation team will already understand the operational procedures, with processes broken down to the smallest steps before applying End-of-Arm Tooling.

-

Inspection robot: internal drones, automated NDI (ultrasound/thermography robot). Using robots for inspection is crucial for the future as the number of inspection points increases (a civil aircraft has about 1-4 million parts), the tasks are highly repetitive, and require extremely professional and responsible personnel.

CT UAV self-evolving composite molding plant

Inside the plant

4. Smart Factory 4.0+

- Full Lifecycle Digital Twin: from plant design (BIM) → raw materials → manufacturing → inspection → UAV operation → customer feedback → repair services.

- IoT sensors in the production line: real-time monitoring of temperature, pressure, resin flow, and porosity.

- AI + Machine Learning: optimizing lay-up, detecting defects, and predicting failures before they occur.

-

Traceability: ensuring 100% traceability of materials, lot numbers, and processes.

5. Quality Control via Automated QA/QC - Applying Robot Arms. The plant operates according to the AS 9100 standard pre-audit.

General: AS 9100 is an upgrade of ISO 9001 specifically for the aerospace industry.

QA (Quality Assurance): AS9100 establishes systems, processes, and certifications to ensure products meet aviation industry standards.

QC (Quality Control): is part of AS9100 requirements (inspection, test, NDT…).

- In-situ NDI: sensors integrated into the mold for continuous inspection throughout the curing process, without waiting for the final product.

- AI defect detection: camera + AI vision + ML to detect defects such as fiber misalignment, bridging, and resin-rich/void areas.

-

Digital QC: Profile inspection using 3D scanning or touch probes for components requiring extremely high precision. All inspection results (NDT, load tests…) are automatically updated to the Digital Twin system, synchronizing data for QA to analyze error frequency and rates and to find solutions with R&D.

Software Systems Typically Integrated in an AS9100 Compliant Company

- ERP (Enterprise Resource Planning) → manages finance, materials, inventory.

- MES (Manufacturing Execution System) → manages production, stages, work orders.

- QMS (Quality Management System) → manages quality, nonconformance, CAPA, audits.

- PLM (Product Lifecycle Management) → manages design, BOM, CAD data.

- SCM (Supply Chain Management) → manages suppliers, CO, CQ certificates.

- Calibration & Maintenance System → manages measurement and production equipment.

-

Document Control System → ensures documents are always the correct version.

AS9100 Standard Connection Model

- PLM ↔ ERP: BOM, product design → directly updated to ERP.

- ERP ↔ MES: Production plan, work orders → coordinated by MES → status updated back to ERP.

- MES ↔ QMS: MES sends QC data to QMS at each stage → manages nonconformance.

- QMS ↔ Supplier Portal: Manages supplier quality, tracks certificates.

- QMS ↔ Calibration System: Automatically alerts when equipment calibration is due.

-

All systems ↔ Document Control: ensures a single standard version.

Within an AS9100 Compliant Company

- NC management is typically linked to QMS software (e.g., QT9, MasterControl, FlinkISO).

- NCRs are linked to MES/ERP → identifies which batch, stage, or equipment caused the error.

- Auditors typically request to see NCR → Root cause → CAPA → Verification.

- This is crucial evidence to prove the effectiveness of the quality system.

In conclusion, the NAACP-class Composite molding plant, combined with AI technology, will be a groundbreaking marvel for CT UAV, clearly asserting its world-class status and providing a firm-as-steel answer to all skepticism and envy, affirming a new era for Vietnam.

Media contact: thi.tran.m@ctgroupvietnam.com

https://www.globenewswire.com/NewsRoom/AttachmentNg/f5671e2c-749b-4089-a67e-370a148ae0f7

https://www.globenewswire.com/NewsRoom/AttachmentNg/d981dbf2-2d8c-49c8-bdfe-63870c1438d9

https://www.globenewswire.com/NewsRoom/AttachmentNg/c1531515-9e80-4fc5-99e4-e929be07a893

https://www.globenewswire.com/NewsRoom/AttachmentNg/1378c460-037b-4077-af22-19006e1a081d

https://www.globenewswire.com/NewsRoom/AttachmentNg/3819d3f2-bd5a-4be8-84af-5ce7b1f69438

https://www.globenewswire.com/NewsRoom/AttachmentNg/b76b6d05-6452-4942-aeb8-79b7d591db06

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.